In 2023, a truly monumental vision took shape in Rama First Nation, capturing global attention and a prestigious Guinness World Record. The world’s largest dream catcher, a stunning symbol of culture, artistry, and community spirit, became a reality. Norweld Inc., based right here in Orillia, is incredibly proud to have played an instrumental role in this historic achievement. Our work on the Rama Dream Catcher was pivotal for acquiring the 2023 Guinness World Record, and this project stands as a powerful testament to our expertise in innovative design, complex engineering, and large-scale steel fabrication.

This wasn’t just another fabrication project; it was a unique fusion of intricate artistic design and demanding structural engineering, requiring a level of precision and ingenuity that pushed the boundaries of conventional construction.

A Monumental Vision: The Challenge of Weaving a Giant

The ambition to create the world’s largest dream catcher was bold and inspiring. Dream catchers hold deep cultural significance in Anishinaabe traditions, traditionally woven to filter out bad dreams and allow only good thoughts to enter. To translate this cherished symbol into a record-breaking structure presented an extraordinary set of engineering and fabrication challenges. The sheer scale demanded a structure that could not only replicate the delicate beauty of a traditional dream catcher but also withstand the formidable forces of nature, all while being a source of pride for the Rama First Nation community and visitors alike.

Norweld Inc. was approached to lend our specialized steel fabrication and engineering expertise to transform this ambitious artistic concept into a tangible, enduring landmark. The task was clear: create a colossal dream catcher that was both aesthetically breathtaking and structurally unshakeable.

Norweld’s Blueprint: Engineering for Unprecedented Scale and Enduring Strength

The first step was to address the immense engineering questions. How do you design a structure of this magnitude to be safe, durable, and true to the traditional form?

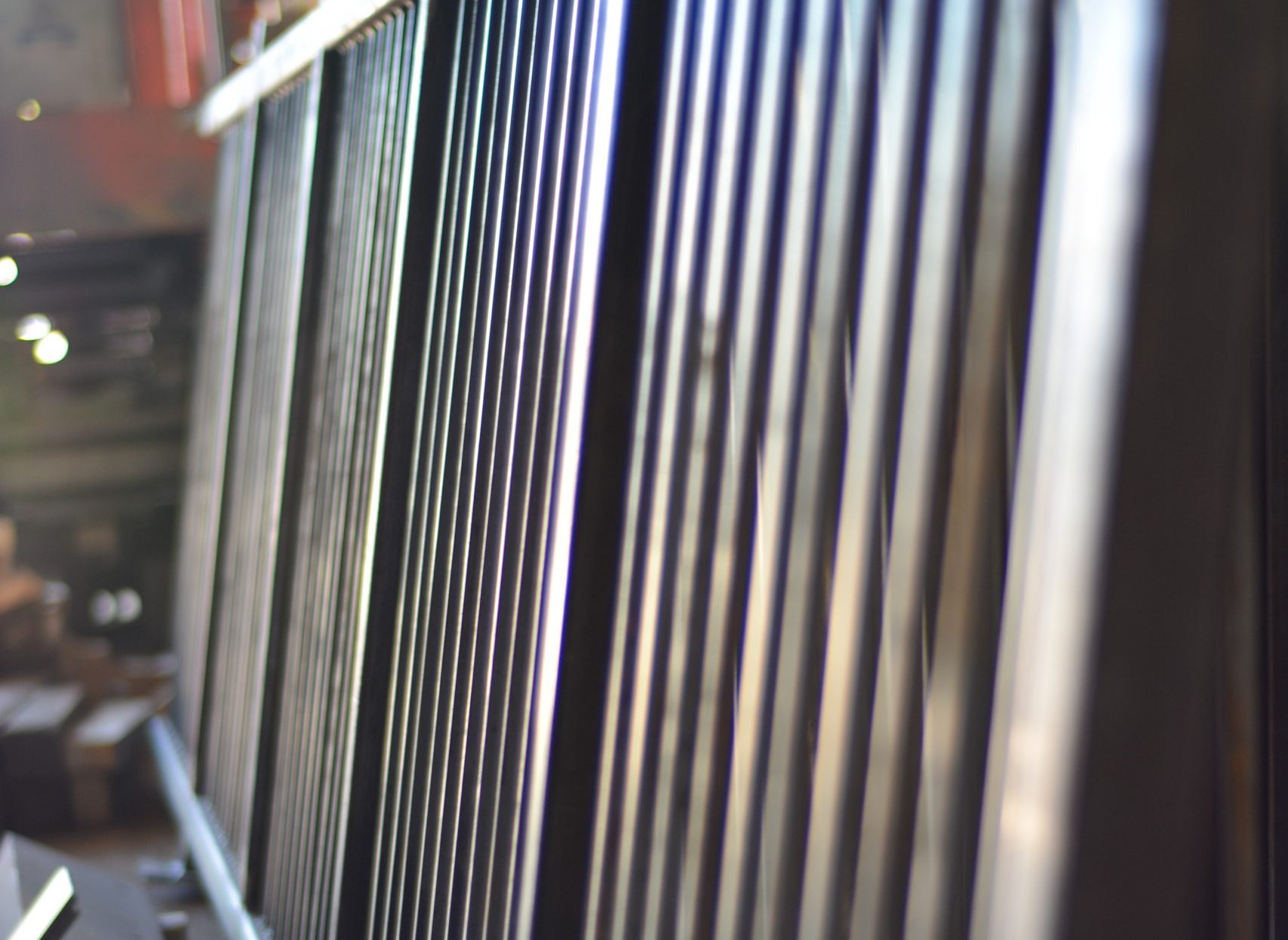

- Material of Choice – Steel’s Resilience: We engineered a durable, weather-resistant structure primarily from steel. Steel was selected for its superior strength-to-weight ratio, its ability to be shaped into complex forms, and its long-term resilience against the harsh Canadian elements. This allowed us to create the massive circular frame and the intricate inner webbing with the necessary structural integrity.

- Weathering the Elements: Given its permanent outdoor installation, weather resistance was paramount. Our engineering accounted for wind load, snow accumulation, and temperature fluctuations. The steel was treated with specialized protective coatings to prevent corrosion and ensure longevity, preserving the dream catcher’s beauty for years to come.

- Precision Engineering for an Artistic Icon: Our engineering team worked meticulously to translate the artistic vision into precise structural plans. This involved sophisticated calculations and detailed 3D modeling to ensure every connection point, every curve, and every segment of the webbing contributed to the overall stability and aesthetic harmony of the colossal structure.

Weaving Steel: The Art and Science of Large-Scale Fabrication

Replicating the delicate, hand-woven appearance of a traditional dream catcher using robust steel, at such an enormous scale, required innovative fabrication techniques.

- Intricate Webbing, Industrial Strength: We successfully replicated the dream catcher’s intricate webbing using specialized techniques. This was perhaps the most complex fabrication challenge. It involved developing custom methods to cut, shape, and securely connect the numerous steel components that formed the web, ensuring each strand was precisely placed to achieve the iconic pattern while contributing to the overall structural matrix. Our CWB-certified fabricators brought their highest level of skill to this task.

- Meticulous Workshop Fabrication: Every component, from the massive outer ring segments to the most delicate-looking pieces of the steel web, was fabricated with painstaking care in our Orillia facility. Meticulous fabrication was non-negotiable. Advanced cutting, bending, and welding processes were employed, with constant quality checks to ensure dimensional accuracy and the integrity of every weld.

- Balancing Aesthetics and Engineering: Throughout the fabrication process, there was a constant focus on maintaining the artistic integrity of the dream catcher. The challenge lay in making a fundamentally strong, industrial material appear as graceful and intricate as a traditional hand-crafted piece, only magnified to an epic scale.

Bringing the Dream to Life: Precision On-Site Assembly

Once the numerous components were fabricated, the next critical phase was transportation to Rama First Nation and the complex on-site assembly.

- Logistics of a Giant: Moving such large and often uniquely shaped steel sections required careful logistical planning to ensure safe and timely delivery.

- A Symphony of Steel: Meticulous on-site reassembly ensured both aesthetic appeal and structural integrity. Our skilled team, equipped with detailed plans and specialized lifting equipment, undertook the task of erecting the structure. This involved carefully joining the massive segments of the outer ring and then systematically installing the intricate steel webbing. Perfect alignment was critical, not just for the dream catcher’s visual symmetry but, more importantly, for its structural soundness. Each connection had to be precise to distribute loads correctly and ensure the stability of the entire edifice.

A Record-Breaking Triumph: Celebrating Precision, Collaboration, and Community

The culmination of this intensive design, fabrication, and assembly process was the official recognition by Guinness World Records. The Rama Dream Catcher was declared the world’s largest.

This achievement showcases our ability to deliver complex projects with precision and excellence. It was a proud moment for Norweld Inc., and even more so, a momentous occasion for Rama First Nation and all who contributed to the project. This record-breaking structure is more than just steel; it’s a landmark, a conversation piece, and a powerful symbol.

While we are experts in steel, we recognize this project was a deeply collaborative effort, and we were honored to contribute our technical skills to such a culturally significant and visually stunning undertaking for our neighbours at Rama First Nation.

Your Vision, Our Expertise in Steel

The Rama Dream Catcher project underscores Norweld Inc.’s unique capabilities in tackling large-scale, unconventional, and complex steel fabrication challenges. From initial engineering design to precision fabrication and on-site assembly, we have the proven expertise to transform ambitious visions into remarkable realities.

If you have a unique, large-scale, or intricate steel fabrication project in mind, whether it’s an architectural feature, industrial component, or a one-of-a-kind installation, Norweld Inc. is ready to engineer your dream. Contact us today to discuss how we can bring our award-winning expertise to your next challenge.